1. The invention:

Rotary Cremating

- The problem

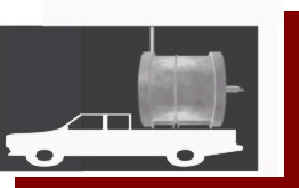

solved: The objective of development

of the solution applied in the invention was to create a piece of

equipment for permanent operation, suitable for the cremation of

several corpses at a time with a single feed hole, which – depending

for size – may even be a mobile piece of equipment.

-

Definition:

The equipment and technology to be presented fundamentally different

from the practices so far, yet it reliability meets all relevant

requirements. It is possible to install 3, 6 or 12 cremating channels within the

external sheet with a single feed hole. The diameter of the external

cylinder depends on the number of cremating chambers installed. The

external parameters of the six channel system is some 30 percent larger

than that of a three channel one. The incinerator of rotative system according to the

invention can be advantageously used for disposing of animal bodies by

incineration as well, particularly in case of danger of spreading of contagious

discases, eg. Mad-crow discase, or mouth and foot discase, when unrelated

incineration of bodies is crucial to prevent spreading of the discase. The unit energy consumption of

the new rotary equipment is some 70 percent lower than that currently

applied equipment. This Rotary Cremating can be fix or mobile and module

equipment.

-

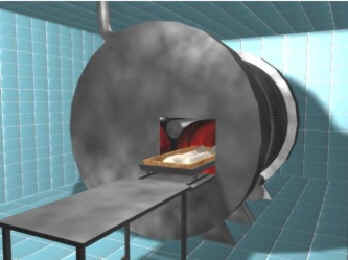

Presentation: There are several

cylindrical cremating channels within an external cover sheet under heat

insulation, rotated around an axis, in the internal surface of which the

cremating units move around on a rolling rack that are kept in a horizontal

position by gravity. It is possible install 3, 6 or 12 cremating channels

within the external sheet with a single hole. The objective of development

of the solution applied in the invention was to create a piece of equipment

for permanent operation, suitable for the cremation of several corpses at a

time with a single feed hole, which – depending for size – may even be

a mobile piece of equipment. The equipment and technology to be presented

fundamentally different from the practices so far, yet it reliability meets

all relevant requirements. Exhaust gas is collected in the section between

the separate cylindrical cremating units, channeled into the standing smoke

collection drum through the holes in the external cover sheet of the

cylinder where it can be released through a chimney via a heat exchanger

after the already applied neutralizing technologies. The gas and the

pre-heated hot air is lead into the equipment at the other extremity of the

external rotating cylinder, enabling the feed required for the optimum

temperature during permanent operation.

-

Application:

Cremation

-

Advantages: Low energy; Consumption;

Efficiency; Security; Environment

protection

-

Stage of development:

Plan

-

Available documentation:

Three-dimensional film on CD,

scale-model, technical process

2. The inventor:

-

Name: Földes,

Gábor

-

Introduction:

3. The

protection:

-

Form:

patent application PCT/HU01/00075

-

Priority: 07. 13. 2000.

- Countries:

- Owner

of patent: The inventor

4. Business

purpose: Co-operating and/or finding

investment partner and selling the patent rights.

5. Contact:

-

Name:

Földes

Gábor

- E-mail:

gabor.foldes@freemail.hu

- Fax:

-

Telephone:

+36

30 941 5263

-

Address:

H

– 1114 Budapest, Bocskai út 27. Hungary

|