The invention

- The

problem to be solved: The developed

nondestructive conductive material

testing method combines high sensitivity

magnetic field measurement with the eddy

current testing (ECT) technique. It

extends the frequency range of the ECT

down to the hundreds of Hz and makes it

suitable for the detection of the flaws

in the deep region of the material.

- Definition:

Fluxset magnetic field sensor is placed

below the exciting coil can be found in

the measuring head. The sensor is located

in the axis of the exciting coil, which

coil axis is perpendicular to the surface

of the inspected material. The exciting

coil generates magnetic field and excites

the investigated material while the

Fluxset sensor measures the response.

- Presentation:

The investigated conductive material is

excited by magnetic field. The local

variation of the conductivity due to the

effect of the flaws or any changes of the

material structure has got influence on

the eddy current distribution inside of

the material and on the magnetic field

over the surface as well. The measuring

head excites the investigated material by

inducing eddy currents in it and detects

the perturbation of the magnetic field

close to the surface. The applied sensor

measures the vector-components of the

magnetic field and provides the two or

three dimensional field map over the

scanned area.

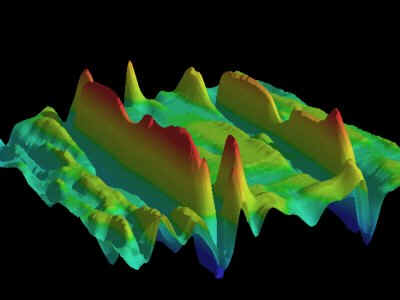

Map

of the measured magnetic field over the surface

- Application:

Fast, touch-less, non-destructive testing

of conductive materials which has got

high conductivity and/or thick walls.

- Advantages:

This technique keeps the benefit of

the high sensitivity and spatial

resolution in the low frequency range

when the exciting magnetic field can

penetrate into the deep region of the

investigated material and can get

information about the micro flaws are

located far from the surface. The

developed probe offers significantly more

information about the perturbations of

the eddy current distribution inside the

material. It detects the vector

components of the magnetic field in each

point of the inspected specimen surface

despite of the impedance coil measurement

is based on the interaction of the

exciting-detector coil and the material,

which can get information only from about

the whole area of the detector coil. The

separation of the magnetic field

detection and the eddy current excitation

makes possible to take apart the spatial

resolution and sensitivity of the probe

from the applied frequencies for the eddy

current induction.

- Stage of

development: Prototype.

- Documentation

available: Several experimental

results, detailed description.

2. The inventor(s)

- Csaba

Sándor Daróczi, researcher,

Research Institute for Technical Physics

and Materials Science

- Antal

Gasparics, researcher, Research

Institute for Technical Physics and

Materials Science

- János

Szöllősy, developer and inventor of

the Fluxset sensor

- Gábor

Vértesy, researcher, Research

Institute for Technical Physics and

Materials Science

3. The

protection

- Form:

Exibition priority

- Priority:

May 4, 2000

- Countries

where it is in force:

4. Business

intention

licence sale

(possible co-operation, investor

participation)

5. Contact

Name: János

SZÖLLŐSY

Phone:

+36 30 924-5399

Fax:

+36 1 392 2222/1740

E-mail:

szjanos@ns.kfkipark.hu

Address:

H-1121 Budapest, Fulemule 12/7B - Hungary

|