The

invention

- The

problem to be solved:

The main aim was to eliminate the

deficiencies and unfavourable properties

(in the course of time the liquid film

becomes interrupted, shrinked over the

supporting surface, the liquid begins to

flow, due to the dirty and greasy

surface) of the liquid films developed

over a supporting surface that are used

in the usual liquid film heat-exchangers

and mixing condensers.

|

- Definition:

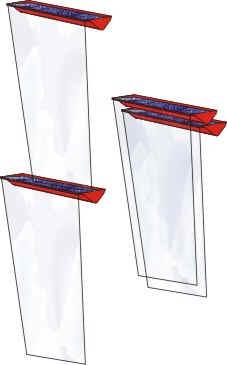

The object of the invention is a

tensioned liquid film heat-exchanger,

without supporting surface, where both

sides of the liquid film are in contact

with the gaseous agents. The liquid film

develops between two nearly vertical

tensioning wires that are slightly

inclined towards each other at their

lower ends and, their length, inclination

angle and distance related to each other,

depend on the properties (surface-tension

constant) of the liquid.

|

- Presentation:

In the invented arrangement the

liquid that overflows on the horizontal

edge of the storage tank practically

falls freely between two tensioning wires

(rods), that are nearly vertical and

slightly inclined towards each other, a

coherent, stable liquid film develops

during the free fall. The dimensions

(film thickness, width) of the liquid

film are constant in the course of time

and, its coefficients of heat and/or mass

transfer are excellent due to the

turbulent flows developed in it.

Practically, an unlimited number of

liquid films can be applied connecting

them one after the other in series or

side by side in parallel. Before the

liquid film would be interrupted its

lower end is immersed into and below the

liquid level of the collecting recipient,

this way, its operation is noiseless. The

automatic development of the liquid film

between the two tensioning wires is

provided by the self-development system,

this way, higher air velocities can also

be used.

|

- Application:

The invented arrangement can

advantageously be used in air

conditioners, mixing heat-exchangers,

cooling towers, water and waste-water

treatment (oxygenation) plants, chemical

industry processes, evaporators, natural

water aerators, gas washers,

paint-sprayer rooms.

|

- Advantages:

Energy saving, noiseless operation,

simple, calculable, low investment costs.

|

- Stage

of development:

A demonstration model and the measurement

results are available.

|

- Documentation

available: Yes

|

The

inventor(s)

- Self

introduction:

The inventor is 45 years old, qualified

mechanical engineer since 1979. He worked

in the fields of public utility design,

construction and operation, in the

metal-industry, and in the lighting

engineering, at first as employed and

later as self-employed.

|

The

protection

- Form:

patent application

- Priority: 25 August, 1999.

- Countries

where it is force:

|

Business

intention: The inventor should like to

sell the licence and he is looking for

development co-operation partner.

|

Contact

- Name:

Csongor CZINTOS

- E-mail:

czintosc@matavnet.hu

- Fax: +36-76 483-297

- Phone: +36-76 483-272 or +36-76 323-675

- Address:

H-6000 Kecskemét, Csáky u. 3.

Hungary

|

|