The

invention

- The

problem to be solved:

To knit racked pattern with about five

times higher productivity as the best

flat-bed knitters.

|

- Definition:

The invention is a knitting

machine with needle beds from segments

racked one after the other. The direction

of the racking is always opposite to the

relative moving of the cambox in

comparison with the needle beds. Since

the effect of the racking on one side is

the opposite to the other side, racking

the segments alternately on one and the

other side, results the same as racking

to and for on one side.

|

- Presentation:

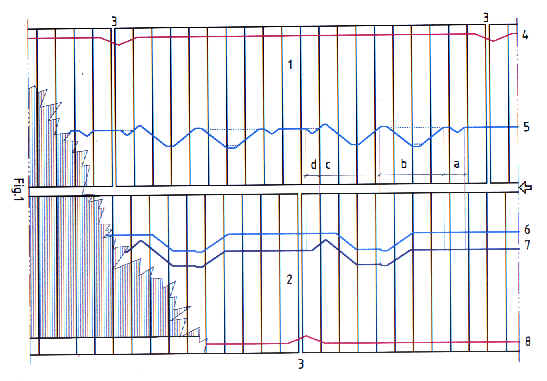

Fig. 1. shows the sketch

of one detail of the needle beds of a

purl (as an example) circular knitter

according to the invention. No. 1 is

the upper No. 2 the lower bed. The

arrow shows the direction of the relative

moving of the needle beds in comparison

with the cambox. No. 3 is the

position of the racking the segments

(here after every ten segments). No. 4

– 8 illustrate the cam races.

No. 5 illustrates the moving of

the upper sliders, No. 6 shows the

moving of the lower sliders, No. 7

is the race of the transfer jacks. No. 4

and No. 8 illustrate the races

controlling the racking of the segments.

The selected needles move along the

continuous line, the non selected along

the dotted line of the curve 5.

According

to the example, while ten segments are

knitted, all the phases of a pattern with

row of transfer switches are completed:

i. e. transferring back the previously

non selected stitches (a),

knitting the new row of loops (b),

and transferring the new non selected

stitches, (By a purl knitter this is

composed of two parts: transferring all

stitches /c/, and transferring

back the selected stitches /d/)

and racking segment by segment.

As shown

in Fig.1., a group of ten segments

on one side are alternately exactly

facing the segments on the other side, or

are racked. So the machine is able to

knit as many row of transfer stitches in

one revolution as many ten-segments races

can form by the cams.

The

segments can be moved by simple

mechanisms from tappets and pins, or by

separate source of power (e. g.

electronic).

The

circular knitter has rotating cylinder

and take-down. The take-down has to be

“racked” as well in such a way, that

it must always facing the same segments.

In the needle beds some unoccupied areas

are required, extending minimum as many

needle distances as the total possible

needle distances of the racking on one

side. At this place the start and the end

of the row of loops can be established.

With an advantageous measurement of these

unoccupied areas, the yarn carriers and

the position of the cams can be changed

here as well.

|

- Application:

To knit outer garments with racked design

by coarsegauged (E4 – E10) circular

knitters. The machine could be a

large-sized two-bed circular knitter as

well.

|

- Advantages:

The circular knitter is able to knit the

same racked design with its high

productivity as the slow flat-bed

machines.

|

- Stage

of development: Prototype

|

- Documentation

available: description of the

invention, and Fig. 2: a possible

form of the mechanism for racking the

segments.

|

The

inventor(s)

- Name(s):

SZÉKELY, Lajos, dr.

- Self

introduction:

Székely, Lajos, dr, engineer, and owner

of a small knitwear factory

|

The

protection

- Form:

Patent pending in Hungary

- Priority: 18.01.2000.

- Countries

where it is force:

|

Business

intention: to sell the invention

|

Contact

- Name:

Dr Székely Lajos

- E-mail:

szekely.lajos@matavnet.hu

- Fax: +361- 410 7193

- Phone:

- Address:

H-1155 Budapest, Vág u. 47.,

Hungary

|