The invention

- The problem

to be solved:

The different mud that remain after leather processing

and galvanisation technologies are hazardous

waste. The invention offers solution for the

extraction of metals and the utilisation of the

remaining mud with an environment friendly technology. The results are given back

to the industry and agriculture for reuse.

|

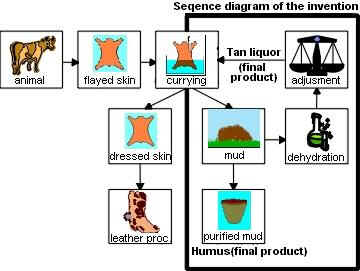

- Definition:

The mud containing heavy metals are

treated in two phases after the filtering. The

filtrate with the help of electrolysis and

osmosis, after the parameters are adjusted, is

given back to the factories for reuse. The heavy

metals are cleared off from the dry material with

washing in pulsating electric field and with pH

adjustment. The mud containing no metal is

utilised as humus, while the washing liquid is

handled together with the filtrate.

|

- Presentation:

The pH of the chromic mud is adjusted to

1.5 with sulphuric acid, and under constant

stirring the temperature is kept at 50 – 80 C° for 1.5 hours, while flocculating

agent is added as well. Afterwards the suspension

is filtered, and then after electroflotation

(which is microelement filtration) it is

dehydrated through osmosis. After the

concentration process the chemical adjustment

will follow (tan liquor H2SO4+Cr2

(SO4)3 and the recycled tan

liquor is returned to the leather industry. The

water produced during the concentration after the

osmosis will be utilised in the washing process.

The residual dry material will be washed after

homogenisation at pH 2 – 5, in a pulsating

electric field, at a 0 –80 V/cm field intensity

in every 10 –20 seconds. The washing process is

continued until the chromic content of the dry

material decrease under the permissible

1000-mg/kg value. The washing liquid is also

concentrated by the help of osmosis, and the

resulting solution, which contains chrome, will

be adjusted at the same level that of the tan

liquor and will be returned to the washing cycle.

The cleaned dry material is mixed with humite,

and straw and can be utilised in the agriculture

as humus. In case the tan liquor cannot be

returned into the leather processing technologies

as it is, than from the concentrated chrome III

solution chome alumen (KCr(SO4)2-12H2)

is produced, that is neutralised with potassium

carbonate, or potassium hydroxide added, and

after evaporation, and cooling the chome alumen

is filtered.

|

- Application: Environmentand

recycling.

|

- Advantages:

The protection of the environment. The reuse,

recycling of hazardous wastes in an environment

friendly way. The production of useful recycled

materials from the waste for the industry and the

agriculture. The recycling reduces the amount of

the hazardous material input in waste management.

Economic advantages.

|

- Stage of

development:

Examined successful semi-plant experiment.

|

- Documentation

available: Yes; the experimental machine

will be exhibited during the fair

|

The inventor(s)

- Name(s): Zoltán

SZABÓ Dr.

- Self

introduction:

He borns on 26/05/1963 in Budapest, He is a

chemist. He is member of MAFE since 1991.

Inventions are mainly about the utilisation of

heavy metal muds. Disabled pensioner, inventor

with three children.

|

The protection

- Form: Exhibition

priority

- Priority: 04/05/2000

- Countries

where it is force:

|

| Business

intention: Finding the consumer, the buyer, the

investor or the initiator of the invention |

| Contact

|