The

invention

- The

problem to be solved:

Development of a

new milling technology by the application

of new type rotating mills to ensure a

product quality better ever before in a

cost-effective way, with less emission to

the environment.

|

- Definition:

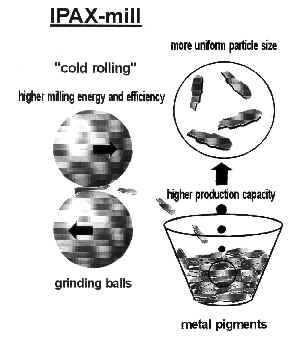

The

invention is a new construction of

rotating mill, so called IPAX-mill, by

application of which high milling energy

and efficiency are used to thin and chop

the particles of the material to be

milled by a cold rolling and shearing

effect

|

- Presentation:

The high

efficient milling feature of IPAX mills

are due to those new construction

elements (e.g. milling works, drain valve

etc.) which can optimally be adjusted to

the different milling technologies making

possible:

- The optimization

particle size ranges and the

surface chemistry processes of

the milling products,

- Minimization of

the cycle time and energy

consumption, and environmental

contamination,

- Efficient milling

of powders having changing

consistency to a great extant

With these characters

the invention can equally be applied in

various milling technologies, the

universal applicability is well

demonstrated in the new metal pigments

manufacturing technology.

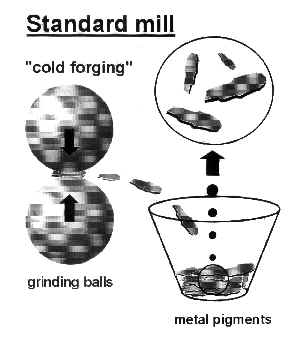

The general problem of the traditional

pigment paste technology is that during

the milling process the size and form of

the particles as well as the

consistencies of the pulps are changing

significantly.

Therefore metal based pigments are

traditionally produced by thinning and

chopping with cold forging the metallic

grains in standard ball mills at low

milling energy and efficiency. That

process needs a lot of electrical energy,

the particles size range is too wide, and

the ball mills are noisy, their emission

to the environment is too much. The

presently known rotating mills having a

higher efficiency are not suitable to

mill pulps changing in a wide consistency

range due to their special construction,

for example to provide pigment pastes.

The present invention offer a solution

for the first time for manufacturing

metal pigment products by increased

milling energy and efficiency in IPAX

mills, thinning and chopping the metallic

grains by cold rolling effect.

The special deformation effect and the

high milling energy result in more

constant particle sizes and more perfect

surface chemical processes, respectively

in the metal pigments produced. The

efficient milling results in significant

electrical energy saving and the

injurious impurity emission to the

environment is minimal.

Operation of IPAX-mills is safely; the

maintenance can quickly be accomplished.

By this new technology any kind of cold

ductile metals such as: Al, Cu, Sn, Zn,

bronze, noble metals, etc. can be

processed in metal powder or flake or

waste metal granules (cut foil, cable

crushing, chips, rasps etc.) forms. In

IPAX-mills water-, white spirit-,

paraffin oil-, gaseous oil-, xylene-,

glycol- (etc.) based pigment pastes, and

metal pigments with 100 % dry content can

be manufactured.

|

- Application:

Metal pigment and

pigment paste productions for

manufacturing metal base paints, gas

concrete, and plant protection materials.

Production of organic and inorganic

powders, suspensions, and masses having

even particular size for paint,

pharmaceutical, and food industry.

Powder basic material production for

powder metallurgy (producing sinter

metals, magnetic materials, mechanical

alloying (MA), metal matrix composites

(MMC) etc.) products.

|

- Advantages:

Application of IPAX

mills compared to the traditional ball

mills means:

three times higher

production capacity,

significant electrical energy saving

(60-70%),

more even particle size products,

more perfect surface chemical processes,

with enhanced raw material utilization

(20-25%),

reduced injurious impurity emission to

the environment (80%)

noise reduction (20-25 dB),

modern safety technique, thereforebetter

product quality (7-10%),

higher stability of product quality

(50-70%),

reduced technological pollution to the

environment,

up to date health safety, and less human

expenditure.

The invested capital can be

gained back in 2-3 years due to the technical

and economical advantages of the invention.

|

- Stage

of development:

The new production

technology was accomplished in pilot

plant and industrial scales, too.

Reference plant: Pigment paste

factory of Kőbánya Light Metal Work

Ltd., in Kecskemét, Hungary.

|

- Documentation

available: Yes

|

| The

inventor(s)

|

The

protection

- Form:

Patent (HU

208 842), utility model, patent

application (HU P 98 00274)

- Priority: April 15, 1992;

February 10, 1998

- Countries

where it is force: Hungary

|

| Business

intention: Realization

of the patents to equipment manufacturers, and

applicators by producing IPAX mills. Searching

for investing partners for the privatization and

finishing of the innovation of the Pigment paste factory of

Kőbánya Light Metal Work Ltd. |

Contact

- Name:

László

Ipacs

- E-mail:

aluplan@mail iif.hu

- Fax: +361- 341 2128

- Address:

H-1074

Budapest, Vörösmarty u.9, Hungary

|

|