- The problem

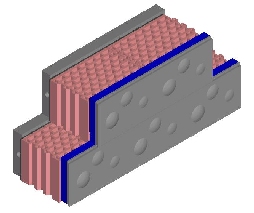

solved: The main aim was to design masonry blocks for

bricklaying purposes that can be fitted together like the LEGO

elements and, to ease the bricklaying process.

-

Definition:

The objects of the invention are: the special

shaping of the masonry blocks abutting surfaces, that are producing a self

supporting wall when the masonry blocks are put over and at the side of

each other, as well as, the bricklaying process.

-

Presentation:

This process and masonry block facilitate to promote the use of the prefabricated elements in the building industry. The design is accomplished using a module that is part of the design software. After the electric and engineering design of the building, the masonry blocks are generated from the ready made working design and these are saved in separate files. Afterwards, the design data can be read-in into the production line. In the ready made masonry blocks the required holes and the actually required fittings are already built in.

At the end of the manufacturing process the masonry blocks are packed according to their installation place identification number as it is indicated in the execution scheme. No exterior scaffolding required during the bricklaying.

-

Application:

These masonry blocks can be advantageously used

in the building industry and in the development of new building systems.

-

Advantages:

Facilitates the utilisation of the new possibilities provided by the computerised technology. The major part of the local tasks of the bricklaying work are already done in the manufacturing plant. Using the properly shaped masonry blocks the posterior assembly of utility engineering fittings becomes also facilitated. The assembly of the masonry blocks can be done to the full using a minimum of auxiliary tools.

-

Stage of development:

Design software, graphic representation, scale

model are available.

- Available documentation: Yes

2. The inventor:

Mr. Jenő LÉVAI

-

Name: Jenő LÉVAI and János TISZAVÖLGYI

-

Introduction:

Mr. Jenő LÉVAI is 45 years old machining

technician, toolmaker. Under his professional leadership a metal machining

company, established in 1980, achieved to occupy a leading market position

in Hungary. Two years before he was engaged in marketing and installing

shut-off devices (doors, windows, etc.).

Mr. János Tiszavölgyi is 45 years old, mechanical technician. He is a tradesman from 1992 and during the last three years he is working in the field of establishing environment protection technologies in Hungary.

3. The protection:

- Form: patent application, (registration no.: P0204326)

- Priority: 13 December, 2001.

- Countries:

- Owner of patent: The inventors

4. Business purpose: Licensing and looking for manufacturing partners

5. Contact:

- Name: Jenő LÉVAI

- E-mail: yano1@enternet.hu

- Fax: +36 79 521 220

- Telephone: +36 72-448 316, +36 30-426 17 66

- Address: H-6501 Baja pf 164, Hungary