The

invention

- The

problem to be solved:

High quality can be produced and in the

same time production cost reduced,

significantly comparing to the

traditional technology.

|

- Definition:

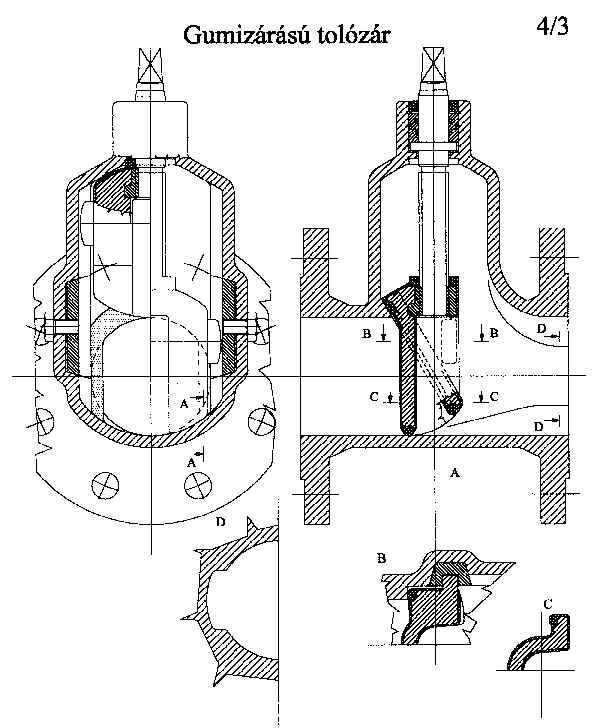

The flanged gate valve is

designed to be mounted between flanges.

The gate is mountable into the

single-piece cast housing through the

flow tunnel. The gate body is supported

by bearing, and the lug of the guide rail

is made of the same material as the gate

body

|

- Presentation:

The gate valve housing is made

of a one piece eliminating the bonnet.

The gate is mounted into the housing

through the tunnel. The tunnel is widened

in the direction of the valve mounting to

facilitate the guide lug approach. After

mounting the gate through the tunnel the

guide bearing of the gate can be mounted

in the fully open state of the valve. The

bearing is secured by sealed bolts. The

cast gate body is rubber coated. The

sealing surface of the gate is horseshoe

shaped on the top and sides. On the

bottom a large diameter cylindrical

surface is formed joint by radius to the

sealing surface on the sides. The bottom

part of the sealing surface wraps around

the spindle cavity. The gate body is

effectively open from the bottom so that

to avoid blocking of the movement of the

spindle.

The economical design of this gate valve,

as compared to the conventional gate

valve design, results in substantial

weight reduction. The size reduction

facilitates the mounting of this valve

between the flanges similarly to the

blade type gate valve. For the mounting

bolts, holes located on the upper and

center part of the flanges are threaded

blind holes, the rests are through holes.

|

|

|

- Advantages:

-No centre beading, consequently its

machining, sealing and securing are

saved.

-The valve guide is made of the same

material

-The slide way eliminates fretting

corrosion

-Single-piece cast housing has increased

rigidity

|

- Stage

of development: Operation is

introduced by an prototype, model is can be seen.

|

- Documentation

available: Yes,

partially available.

|

The

inventor(s)

- Self

introduction:

I had worked for a industrial valve

manufacturer factory as a designer,

responsible for the development of valves

for pipelines.

Since I have been retired I started to

use AUTOCAD system, and I work on the

developing of valves according to my

conception.

|

The

protection

- Form:

- Priority:

- Countries

where it is force: Hungary

|

Business

intention: seeking for utilisation

co-operation.

|

| Contact

|