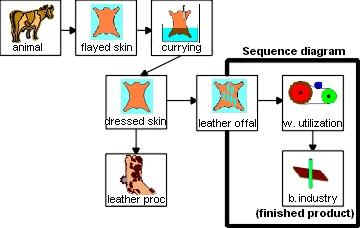

- The problem

to be solved:

The problem to be solved : The different leather

pieces, cuttings, strips and trims issued during

leather processing and leather cutting

technologies is called scrap leather or leather

offal, which is hazardous waste. The processing

companies are storing, accumulating these

materials and usually not in environment friendly

ways. The invention is going to solve this

problem with returning the wastes into the

technological processes after the extract and

bonding the chrome oxide content, this way

avoiding that the heavy metals should penetrate

the soil.

|

- Definition:

The scrap leather, leather offal is

ground, and after grinding it is mixed with

polymers. The mixture is extruded afterwards into

the tool mould of the end product.

|

- Presentation:

The leather offal is ground in shredder,

then dried. The shred then mixed with ethylene of

basic vinyl acetate in an internal mixer. The

distinctive feature of the end product is reached

with further polymers added and mixed. The vinyl

acetate for bonding the chrome content is the

essence of the invention. The mixture is extruded

afterwards into the tool mould of the end

product. The temperature, speed and other

parameters of the extrusion are determined by the

end product, yet the temperature should not

exceed 150C°. Further technologies such as

colouring, hardening, softening etc. can be done

the same way that is used with plastics. The

leather content of the end product produced this

way may be as high as 80 %. The waste from the

manufacturing of this type of end products can be

reused in the technology.

|

|

|

- Advantages:

The protection of the environment. The reuse,

recycling of hazardous wastes in an environment

friendly way. The production of useful recycled

materials from the waste for the building

industry. The recycling reduces the accumulation

of wastes and the penetration, permeating of

heavy metals can also be ceased. Economic

advantages, storage capacity can be reduced, the

end product can be cheaper.

|

- Stage of

development:

Examined successful semi-plant experiment

|

- Documentation

available: Yes; the experimental machine

will be exhibited during the fair

|

The inventor(s)

- Name(s): Zoltán

SZABÓ Dr.

- Self

introduction:

He was born on 26/05/1963 in Budapest. He is a

chemist. He is member of MAFE since 1991.

Inventions are mainly about the utilisation of

heavy metal muds. Disabled pensioner, inventor

with three children.

|

The protection

- Form: Exhibition

priority

- Priority: 04/05/2000

- Countries

where it is force:

|

| Business

intention: Finding the consumer, the buyer, the

investor or the initiator of the invention |

| Contact

|